Access to electricity in buildings is a continuing world challenge, especially in undeveloped countries and refugee camps. Here, electricity is simply unavailable or unreliable. Light at night is known to significantly enhance productivity and education, by allowing life and study to continue outside the limits set by the rising and setting of the sun. Many electronic devices such as mobile phones are also significantly enabling to economic and educational development.

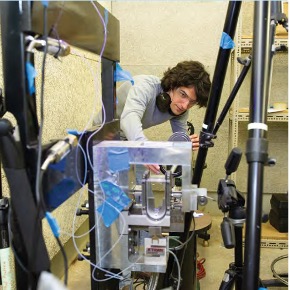

Dr Leigh Aldous (King’s College London), Professor Patrick Phelan (ASU) and Associate Professor Robert Taylor (UNSW Sydney) have developed a thermogalvanic brick that generates electricity as long as the two faces of the brick are at different temperatures. This is an application of thermoelectrochemistry, which generates a thermogalvanic cell, as well as 3D printing technology, which allows strong, plastic bricks to be prepared.

The electricity is produced due to balanced electrochemical reduction and oxidation processes occurring inside the brick at the two faces. As long as the electrodes at these faces are at different temperatures, the electrochemical reactions occur and electricity is generated. The compounds inside are not consumed, do not run out and can never be overcharged. As long as there is a temperature difference there can be electricity. For example, if a house or shelter’s outside wall is sunny and hot, but the interior is shaded and cool, electricity can be produced by the wall.

By using gelled water inside the brick and adding a 3D printed interior based upon a Schwarz D minimum surface structure, the thermogalvanic bricks are stronger than household bricks. These interiors are designed to allow the electrochemistry to occur, and also serve to improve insulation. By using such bricks to build habitations in electricity-deficient areas, it is hoped that significant benefits could be achieved.

The researchers have now filed a patent and a USA-based company, VBeck LLC, has also been established. Notably, undergraduate students were instrumental in progressing the work this far. This includes two King’s Chemistry students; you can hear Conor Beale talking about the project in this BBC interview, and Florence Stoffel in this YouTube video. Benjamin Obeng, an ASU Mechanical Engineering student, also helped significantly; he is a named inventor on the patent, and also features in the YouTube video above.

Other useful information

In a recent paper published in June 2020: Using iron sulphate to form n-type and p-type pseudo-thermoelectrics: non-hazardous and 'second life' thermogalvanic cells by Dr Aldous et al it states firstly that approximately two-thirds (67%) of the energy deliberately generated by mankind is currently lost as heat and secondly that solid-state thermoelectric systems and liquid-state thermogalvanic systems and devices that exploit entropy, i.e. the measure of the amount of energy which is unavailable to do work, present tremendous potential for improving global energy efficiency.

This article was amended on 22nd October 2020

For further enquiries contact Bisi Olulode, Communications Officer Olabisi.olulode@plusallliance.org